QUOTES

CNC WIRELESS COMMUNICATION

Increase your company’s productivity with CNC Wi-Fi technology

CTN develops innovative devices that facilitate communication between CNC machines and computers/smart devices, eliminating the need for cables. With Wi-Fi, Bluetooth, and Ethernet connections, our devices make program sharing faster, more efficient, and secure.

To ensure maximum compatibility, they integrate directly with CNC machines through RS-232/Serial (enabling online machining), LPT, PCMCIA, Ethernet, and USB. Compatible with dozens of industrial controllers, including SIEMENS, FANUC, MACH, MITSUBISHI, and others.

Our technology enables wireless transmission of up to 600Mb/s, allowing simultaneous program sending even while the CNC machine is operating. All this with optimized performance, whether in open environments or with physical barriers.

Eliminate cables, reduce downtime, and optimize your production with CNC Wi-Fi communication.

The most suitable choice

The best choice for data transmission depends on the characteristics of the CNC machine and the distance between the computer and the machine. With the right technology, it is possible to ensure speed, stability, and security in communication between devices.

MAIN ADVANTAGES

- - Online machining without the need for additional software.

- - Automatic system, intuitive and easy to use for any operator.

- - Expanded storage of up to 250GB external on CNC machines.

- - Direct access to CNC programs stored on the company’s server.

- - Unlimited communication, efficient even with physical barriers.

- - High-speed transmission, ensuring fast and stable communication.

- - Protection of communication ports, preventing damage from power surges.

- - Programs requested automatically directly from the CNC machine.

- - Low cost and fast installation in record time per machine.

- - Access to the peripheral without the operator leaving the CNC machine.

- - Instant program sending, even during the machining process.

- - Minimal maintenance, less than 1% for the wireless system.

- - Total flexibility for changes in the industrial layout.

- - Global connection, allowing program sending between headquarters and branches, directly to the CNC server, with access from the machine’s panel.

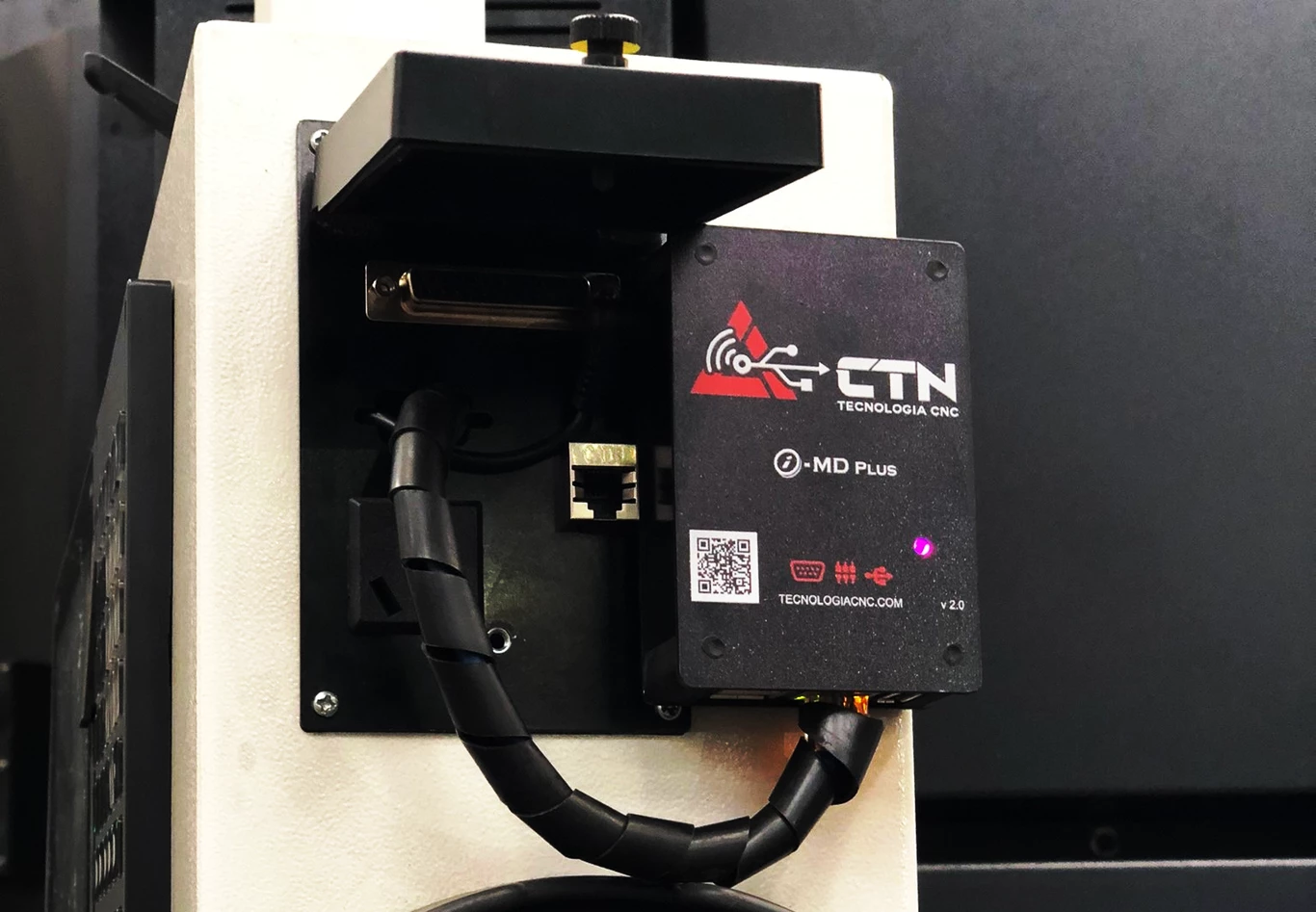

i-MD Plus Advantages

- - Fast and secure CNC file transfer via Wi-Fi.

- - Automated backup of machine data.

- - Instant transmissions without stopping the machine.

- - Advanced protection against viruses and digital threats.

- - 2GB internal storage, expandable for greater capacity.

- - Preservation of communication ports, eliminating wear from continuous peripheral use, such as USBs.

- - Time savings, eliminating unnecessary factory movements.

- - Factory layout flexibility, without the need for physical cabling.

- - Real-time monitoring for machines compatible with industrial protocols via RJ45.

- - Anatel-approved product, ensuring quality and safety.

MODULES

i-CARD

Connects to the PCMCIA port and allows sending and receiving programs via Wi-Fi, sharing folders seamlessly with multiple platforms such as Windows XP/7/8/10, Android, or macOS.

Technical SpecificationsWi-Fi with WPA-WPA2 encryption, 802.11 b/g/n 2.4GHz. Support as a DHCP client for IPv4. Support for Windows Sharing Protocol. Provides storage on CNC machines up to 1GB external. Connects to the PCMCIA port of the CNC machine. High-speed data transmission. No external power supply required.

i-MD Plus Ethernet

Connects to the Ethernet port and allows sending and receiving programs via Wi-Fi with multiple platforms such as Windows XP/7/8/10, Android, or macOS, in addition to having a configuration panel.

Technical SpecificationsWi-Fi with WPA-WPA2 encryption, 802.11 b/g/n 2.4GHz. Ethernet port 10/100Mb/s. Support for Windows Sharing Protocol. Support as a DHCP client for IPv4. Web configuration panel in Portuguese / Spanish / English. Provides storage on CNC machines up to 250GB external. Ethernet connection port for the CNC machine. High-speed data transmission. Internal Wi-Fi antenna. Support for external USB Wi-Fi antenna 802.11a/n/ac 5GHz. Power supply 110v - 220v.

i-MD Plus USB

Connects computers to CNC machines via Wi-Fi to send and receive programs, connected to the CNC machine through USB 1.0 / 2.0 / 3.0 ports for sending and receiving files.

Technical SpecificationsWi-Fi with WPA-WPA2 encryption, 802.11 b/g/n 2.4GHz. Support for USB 1.0/2.0/3.0 ports of CNC controllers. Support for Windows Sharing Protocol. Support as a DHCP client for IPv4. Web configuration panel in Portuguese / Spanish / English. Provides storage on CNC machines up to 250GB external. High-speed USB / Wi-Fi data transmission. Internal Wi-Fi antenna. Support for external USB Wi-Fi antenna 802.11a/n/ac 5GHz. Power supply 110v - 220v.

i-MD Plus RS-232/Serial

Connects computers to CNC machines via Wi-Fi to send and receive programs through the RS-232 or LPT port.

Technical SpecificationsWi-Fi with WPA-WPA2/WPA3 encryption, 802.11 b/g/n 2.4GHz. Support for RS-232/Serial port on CNC controllers. Support for Ethernet port 10/100. Support for high-speed online machining. Support for Windows Sharing Protocol. Support as a DHCP client for IPv4. Provides storage on CNC machines from 2GB external. High-speed data transmission. Internal Wi-Fi antenna. Web configuration panel in Portuguese / Spanish / English. Support for external USB Wi-Fi antennas 802.11a/n/ac 5GHz. Power supply 110v - 220v.

CTN Technology

Founded in 2010, it is a pioneer in the development of wireless communication in the state of Minas Gerais, and also has a qualified team in sales, consulting, training, and CNC technical support.

What we do

We provide wireless communication technology for CNC machines, as well as training and machining support.

Why CTN?

CTN Technology is a pioneer in developing technology for CNC automation, prioritizes excellence in services provided, and is constantly updated to deliver the best in technology to clients.